Japanese mustard spinaches are grown at an institute in Habikino, Osaka, with carbonized pig manure applied as a fertilizer. The planter below does not have the fertilizer applied.

Keita Takeuchi

A research team including Hitachi Zosen Corp. has discovered that phosphate rocks, the main raw material for chemical fertilizers, can be replaced by phosphorus coal extracted from carbonized pig feces to the maximum of 40 percent to create a fertilizer with the same quality.

Operation tests were conducted by Osaka-based Hitachi Zosen, University of Miyazaki, Kumamoto University and Research Institute of Environment, Agriculture and Fisheries, Osaka Prefecture.

Swine manure is considered a low-cost natural resource, but an effective way to utilize it has not been developed. Its procurement cost will be low, since hog raising farms are concentrated in regions such as Kyushu and Kanto.

On the backdrop of rising prices of phosphate rocks, all of which are imported from abroad, Hitachi Zosen hopes to start production and supply business of phosphorus-containing coal made from swine manure before the end of fiscal 2015, assuming that the product will be competitive enough in terms of prices.

The operation tests were sponsored by the Ministry of Agriculture, Forestry and Fisheries to seek ways to recycle pig excrement.

Since 2009, the team has been working on developing technology to extract phosphorus from pig manure, and, after succeeding in fiscal 2012, has analyzed the potential of phosphorus-containing charcoal as a fertilizer.

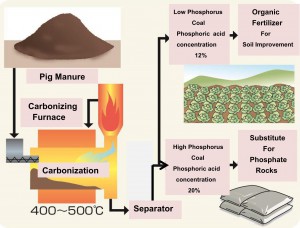

Phosphorus-containing charcoal is produced by mixing pig feces with sawdust and activated sludge, and then carbonizing it at a temperature of 400 to 500 degrees. The charcoal is classified into two types, one with high concentration – about 20 percent – of phosphoric acid and the other with low concentration of about 12 percent. 120 kg of high phosphorus coal and 180 kg of low phosphorus coal can be produced from a ton of pig manure.

Hitachi Zosen conducted experiments of partly replacing high phosphorus coal with phosphorus rocks to manufacture fertilizers. The firm found out that a maximum of 40 percent can be substituted to ensure the same quality as other chemical fertilizers on the market.

The Osaka Prefecture institute applied low phosphorus coal as a fertilizer on Japanese mustard spinaches, and confirmed that no differences can be observed in the growth of the spinaches compared with other spinaches grown with organic or chemical fertilizers on sale.

Because pig feces contain a lot of water, they are unsuitable for wide area distribution. Although some nearby farms use them as fertilizers, it is difficult to consistently assure them the same quality, as components differ according to the product.

Because pig feces contain a lot of water, they are unsuitable for wide area distribution. Although some nearby farms use them as fertilizers, it is difficult to consistently assure them the same quality, as components differ according to the product.

Ryoichi Sakamoto, an official of Hitachi Zosen’s environment, energy and plant headquarters, said if pig feces are carbonized, the product will become lighter, can be preserved and distributed in wide areas. It will help improve soil conditions, he added, saying that the firm is aiming at producing fertilizers by making use of unused domestic resources instead of depending on imported resources.

Phosphate rocks contain roughly 30 percent of diphosphorus pentaoxide, one of the three main elements of fertilizers. Major producers of phosphate rocks are China, the United States and Morocco.

Recently, a large amount of recoverable phosphate ore reserves were found in Morocco, leading to a four-fold increase in the ore reserves, but this does not mean there will be limitless supply in the future.

The prices of phosphate rocks are rising due to increasing agricultural production along with the growth in global population. According to the Finance Ministry statistics, the prices of imported phosphate rocks were JPY 19,702 per ton in 2010, JPY 20,731 in 2011 and JPY 22,312 in 2012, doubling in the past decade. In 2008, the prices went as high as around JPY 40,000, as China, a leading exporter of phosphate rocks, began effectively restricting exports.

It is vital to utilize pig manure and other domestic resources in order to help stabilize agricultural businesses and realize environment-friendly, sustainable farming.

(Jan. 11, 2014)